b1jetmech

New Member

Good to be part of a forum dedicated to aircraft builders and dreamers for that matter!

I drew up plans to build a tandem seat jet..nothing too complex just an entry level jet. It would be all sheetmetal construction with a tapered wing and straight wing chord. Was going to power it with a GE T-85 engine(helicopter turboshaft converted to jet) but saw how expensive those engines can be to maintain so I held off.

Now, a wife and 3 kids later, I put the project on hold in place of something larger.

While doing the research of which powerplant to use. I came to the conclusion there is lack of smaller power plants of a thrust range up to 750 lbs. However, there is a good availability of RC/UAV turbines with a thrust range up to 250 lbs. However, I do want more thrust with less fuel consumption.

So I took upon myself to design and build a small turbofan engine and go from there.

A turbofan engine can use half the fuel depending on design/bypass or using the same amount of fuel and get twice the thrust.

So far, the engine is going to be 24 in long with an 8" fan for starters. I may add a larger fan and LPT later to the "common" core assembly.

A little on my back ground. I was a B-1 bomber engine mechanic for 10 years with a little of F110 engine experience as well. I also do structures and composite repair mostly on airlines/business jets and now General. Structures is fun because it requires creativity to get the job done, especially when it's not clearly defined in the manual.

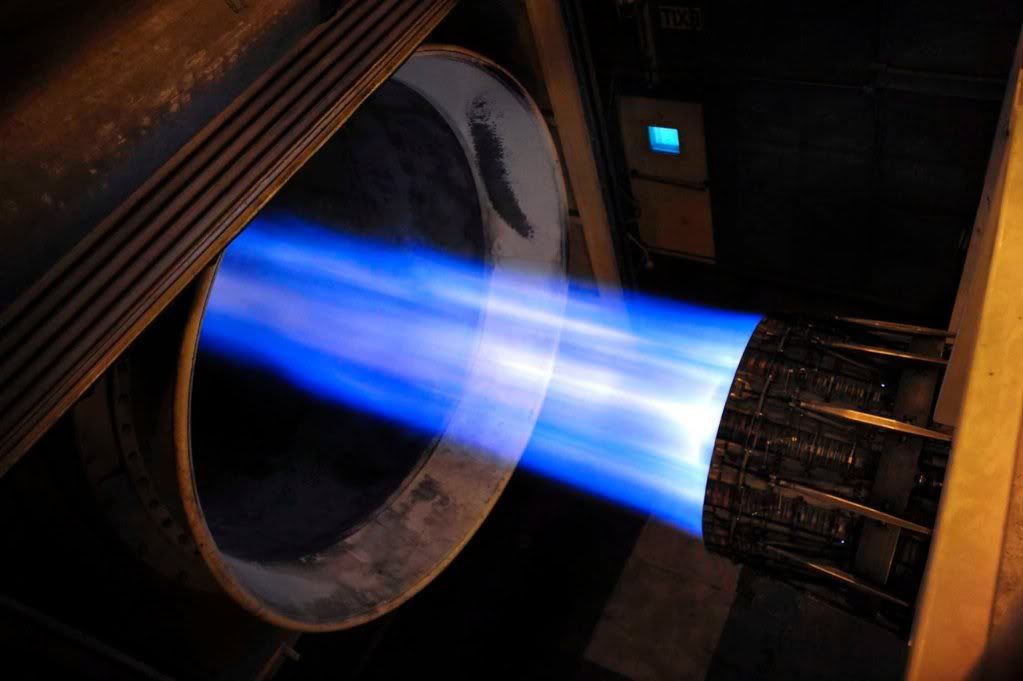

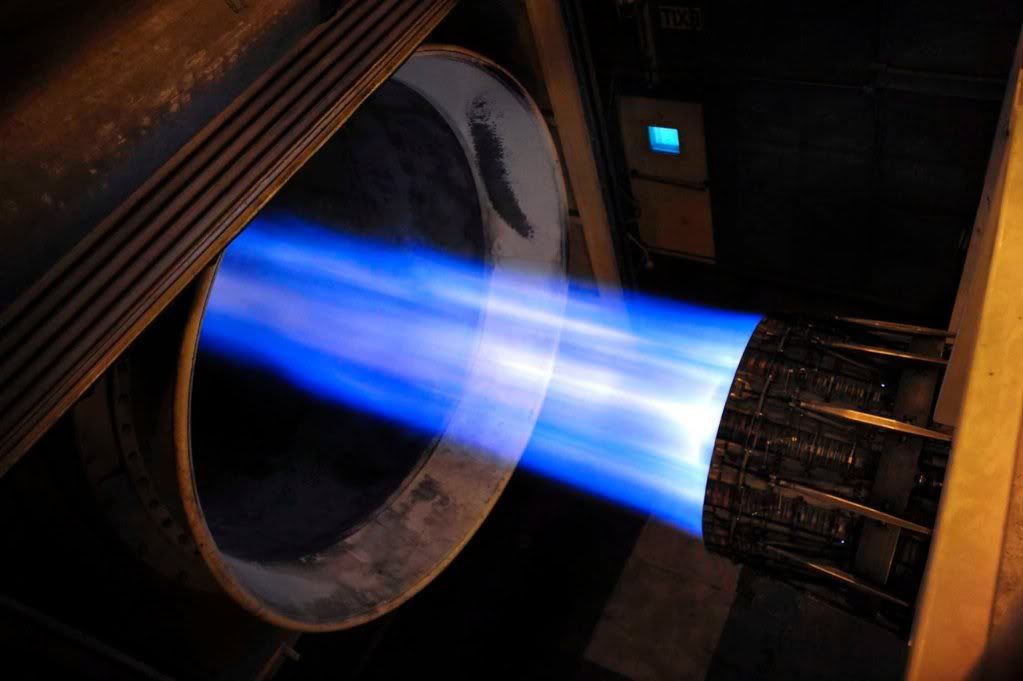

Here is a view from above of engine in burner at test cell: Taken from a stationary camera! Not standing there during burner...TOO LOUD!

Here's an engine on the trailer:

Part of the shop:

We had fun in the the engine shop but sadly it closed down and relocated to Tinker AFB for consolidation.

Chase

I drew up plans to build a tandem seat jet..nothing too complex just an entry level jet. It would be all sheetmetal construction with a tapered wing and straight wing chord. Was going to power it with a GE T-85 engine(helicopter turboshaft converted to jet) but saw how expensive those engines can be to maintain so I held off.

Now, a wife and 3 kids later, I put the project on hold in place of something larger.

While doing the research of which powerplant to use. I came to the conclusion there is lack of smaller power plants of a thrust range up to 750 lbs. However, there is a good availability of RC/UAV turbines with a thrust range up to 250 lbs. However, I do want more thrust with less fuel consumption.

So I took upon myself to design and build a small turbofan engine and go from there.

A turbofan engine can use half the fuel depending on design/bypass or using the same amount of fuel and get twice the thrust.

So far, the engine is going to be 24 in long with an 8" fan for starters. I may add a larger fan and LPT later to the "common" core assembly.

A little on my back ground. I was a B-1 bomber engine mechanic for 10 years with a little of F110 engine experience as well. I also do structures and composite repair mostly on airlines/business jets and now General. Structures is fun because it requires creativity to get the job done, especially when it's not clearly defined in the manual.

Here is a view from above of engine in burner at test cell: Taken from a stationary camera! Not standing there during burner...TOO LOUD!

Here's an engine on the trailer:

Part of the shop:

We had fun in the the engine shop but sadly it closed down and relocated to Tinker AFB for consolidation.

Chase