SpainCub

Well-Known Member

Well, looks like rag cover wings are about as light/strong as you cam mage wings.

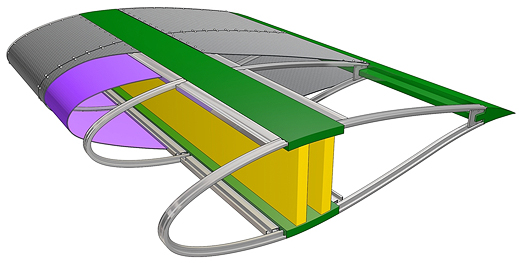

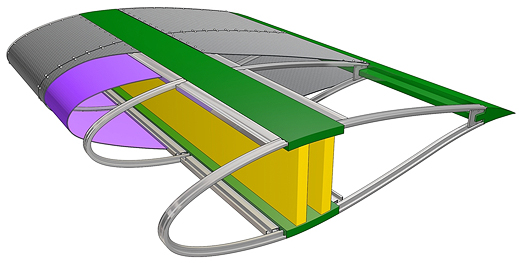

Jarno has done an amazing job (and tank you for sharing it) putting together a wing with a weight/strength ratio utilising composites and fabric covering.

I was thinking to my self, well if I could make composite skins, attach them to a wing like Jarno's without needing to make a plug, then covering it with extremely light fabric, that could be an interesting idea. So I put Google to the work and spend a good half hour reading throughout mostly false positives, then I cam up upon this...

GE is spending millions on the novel idea for making wind turbine blades utilising this concept of fabric covered blades, making them lighter and cheaper to build...

Now considering the efficiency required to extract as much energy as possible from wind power, why is this not been used in light airplanes or sail planes? Other than cost... ( and yes I know that it could be lighter, but hunk of the efficiency in the build ) what am I missing form this concept?

) what am I missing form this concept?

JM

http://m.technologyreview.com/news/508301/ge-hopes-to-make-its-cloth-wind-turbine-idea-fly/

Jarno has done an amazing job (and tank you for sharing it) putting together a wing with a weight/strength ratio utilising composites and fabric covering.

I was thinking to my self, well if I could make composite skins, attach them to a wing like Jarno's without needing to make a plug, then covering it with extremely light fabric, that could be an interesting idea. So I put Google to the work and spend a good half hour reading throughout mostly false positives, then I cam up upon this...

GE is spending millions on the novel idea for making wind turbine blades utilising this concept of fabric covered blades, making them lighter and cheaper to build...

E hopes to make wind turbines far cheaper, and open up new ways to design them, by ditching the stiff fiberglass blades it uses now in favor of turbine blades made out of fabric. GE says the project, which recently received nearly $4 million from the U.S. Advanced Research Projects Agency for Energy, could lower wind turbine blade costs by 40 percent.One way to reduce the cost of wind power is to make larger turbines. But as the blades have been getting larger, the costs of making them have been rising as well, says Wendy Lin, a principal engineer at GE. That’s offsetting some of the advantages of bigger turbines. “We know we really need to make a drastic change in the way we make these blades to bring the cost of the system down,” she says.

GE intends to use a fabric that’s significantly different from the durable fabrics used now in architecture (such as for the roof of the Denver airport) or for gliders. Such projects use polyester, which wouldn’t be durable enough for wind turbines, Lin says. Instead, GE plans to use glass-based fabrics. Indeed, even current fiberglass wind turbine blades start with glass cloth. The blades are made stiff by cementing the fabric with stiff plastic resin. GE plans to use a soft, rubbery resin instead, allowing the fabric to retain some flexibility. That flexibility will make it more resilient than stiff fiberglass, which will in turn allow GE to use less material, reducing materials costs and weight.

Now considering the efficiency required to extract as much energy as possible from wind power, why is this not been used in light airplanes or sail planes? Other than cost... ( and yes I know that it could be lighter, but hunk of the efficiency in the build

JM

http://m.technologyreview.com/news/508301/ge-hopes-to-make-its-cloth-wind-turbine-idea-fly/