I'm interested in exploring implementation of a folding wing version of the Sonex and would appreciate any feedback/ideas.

Background: The Sonex employs a standard AL web spar with proprietary cap strips. The wings are removable (the spars overlap inside the fuselage and are held in place with pins). The single place Onex has fold-up wing panels to allow it to be stored in a single-car garage or to reduce floorspace occupied in a hangar, but I'm not aware of any folding wing modification for the Sonex.

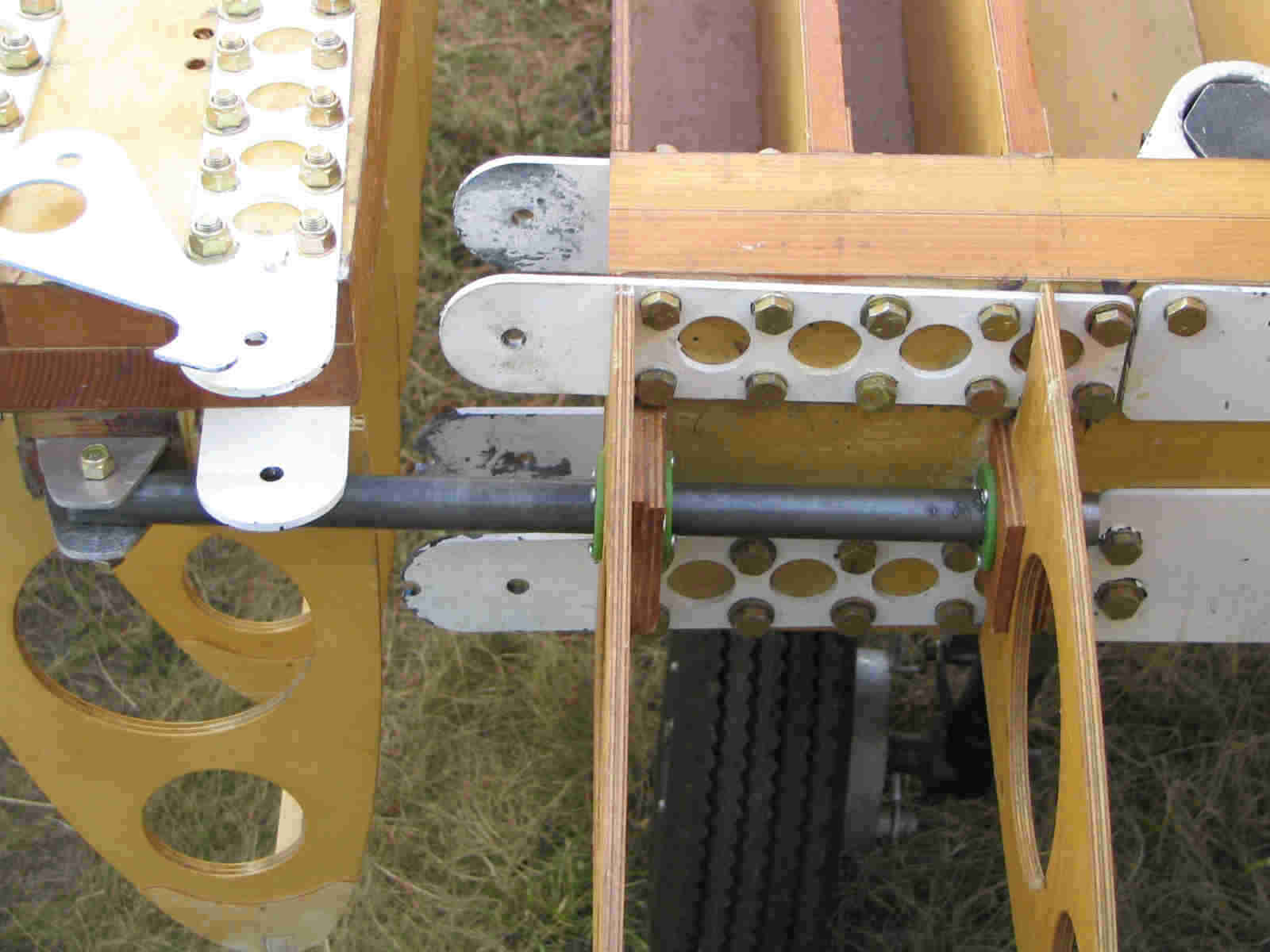

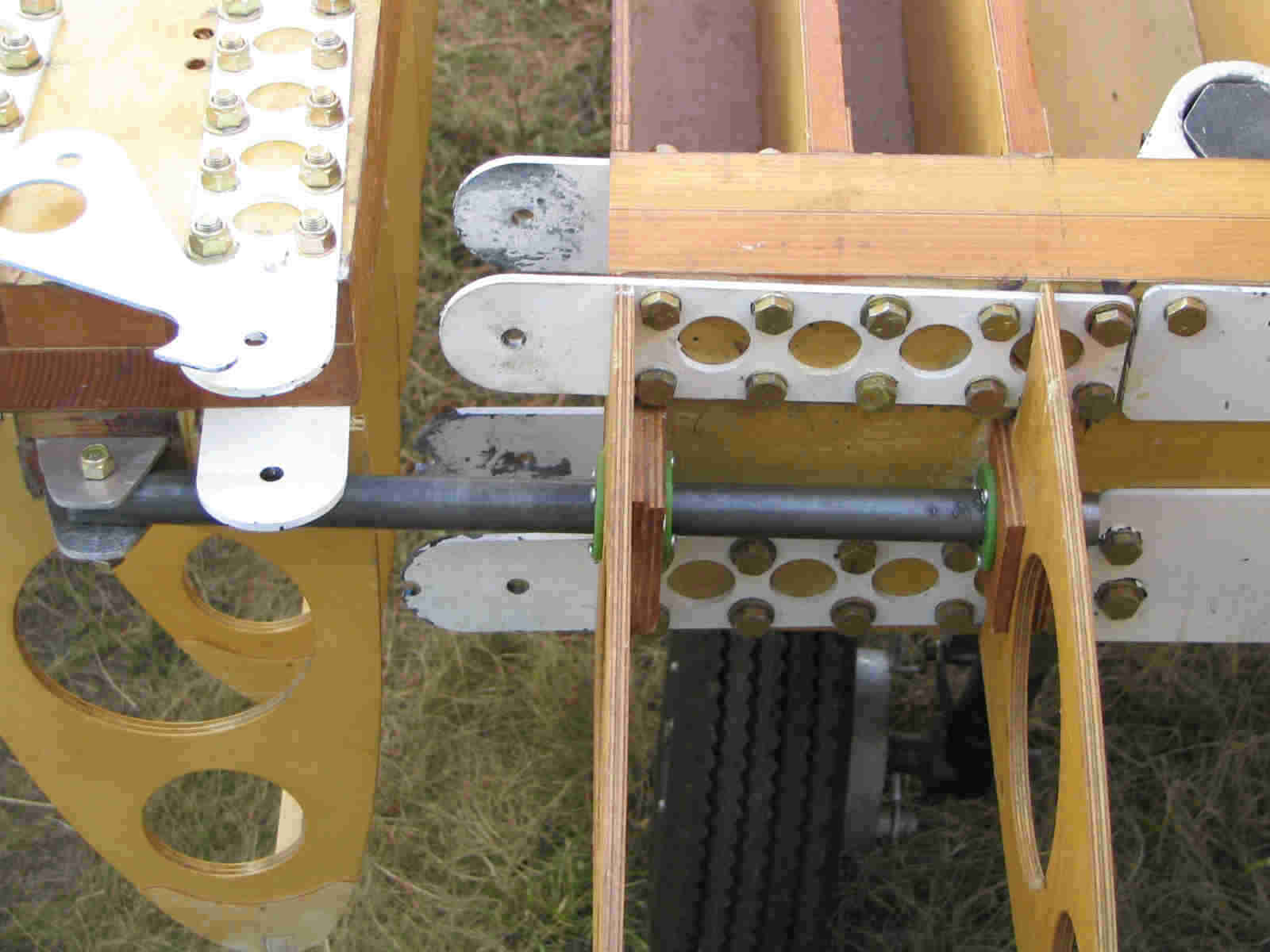

Proposed method: A single pin at the rear spar and pins top and bottom on the main spar. The fold mechanism would be very simple with a pull out/twist wing/fold back method as employed on this KR-2.

(More here: Folding Wing Brackets ) The wing folding mechanism takes no flight loads, it's just a simple fitting that holds the outer wing panel after it's been disconnected and allows it to be pivoted and swing back alongside the fuselage. I don't think all the new hardware (including an extra rib) would weigh more than 10 lbs total.

Some considerations/questions:

1) Where to fold the wing: Options include right at the fuselage or about 20" out on either side.

a) Advantages of folding the entire wing: Narrower fuselage for storing/putting on trailer, simpler (no break in the flaps, etc)

b) Advantages of keeping "stub" wings": It's a handy place to keep fuel, there would be slightly less load on the connection fittings, could mount the main gear on them (another mod--uggh). There would be room for over 10 gallons per side in the stub wings aft of the spar, and even after subtracting some volume for the thickness of a proper fuel cell there would still be room for more than the 16 gallons in the standard Sonex fuselage tank. Obviously, the CG changes would need to be addressed as the CG of the fuel is being moved aft about 30 inches.

2) Excommunication from the Sonex community: It's doubtful any modification of this kind would be smiled upon by Sonex. Very doubtful.

3) Reduction in resale value of the airplane. A given? It would be an "unapproved" modification, so that's going to have an impact. I'd expect prospective buyers would need to see some good engineering analysis, but with that and a few hundred flight hours maybe some people would warm to the idea. It takes 2 people and about 30 minutes to remove or replace the standard Sonex wing, with this modification it would take just 1 person and probably 5 minutes for each side. I think for many folks the advantages will be important--not just for trailering home, but also for fitting more aircraft in a hangar or to allow the aircraft to be kept in a standard 20' shipping container right on the airfield.

4) Aileron connection: The matched bellcranks of the Onex and the Thorp/Sunderland S-18 seem like a great way to accomplish this with minimal hassle. Any other ideas that I should consider?

5) Keep the proprietary spar caps? If they are to be cut anyway, and if an engineered solution for the wing fitting will have to be done/paid for, I wonder if it would be just as well to use a "standard" extrusion rather than custom CNC'ed $1000 spar caps sold by Sonex. Again, Sonex wants builders to use these spar caps, and I understand their reasons. But if we're already going off the reservation . . .

Precision-machined extruded Spar Caps.

(Above images from the Sonex web site: Sonex -- The Sport Aircraft Reality Check! )

Ideas/criticisms are solicited. Anybody know of someone who has done this already? I'm sure others have pondered this.

Background: The Sonex employs a standard AL web spar with proprietary cap strips. The wings are removable (the spars overlap inside the fuselage and are held in place with pins). The single place Onex has fold-up wing panels to allow it to be stored in a single-car garage or to reduce floorspace occupied in a hangar, but I'm not aware of any folding wing modification for the Sonex.

Proposed method: A single pin at the rear spar and pins top and bottom on the main spar. The fold mechanism would be very simple with a pull out/twist wing/fold back method as employed on this KR-2.

| |

Some considerations/questions:

1) Where to fold the wing: Options include right at the fuselage or about 20" out on either side.

a) Advantages of folding the entire wing: Narrower fuselage for storing/putting on trailer, simpler (no break in the flaps, etc)

b) Advantages of keeping "stub" wings": It's a handy place to keep fuel, there would be slightly less load on the connection fittings, could mount the main gear on them (another mod--uggh). There would be room for over 10 gallons per side in the stub wings aft of the spar, and even after subtracting some volume for the thickness of a proper fuel cell there would still be room for more than the 16 gallons in the standard Sonex fuselage tank. Obviously, the CG changes would need to be addressed as the CG of the fuel is being moved aft about 30 inches.

2) Excommunication from the Sonex community: It's doubtful any modification of this kind would be smiled upon by Sonex. Very doubtful.

3) Reduction in resale value of the airplane. A given? It would be an "unapproved" modification, so that's going to have an impact. I'd expect prospective buyers would need to see some good engineering analysis, but with that and a few hundred flight hours maybe some people would warm to the idea. It takes 2 people and about 30 minutes to remove or replace the standard Sonex wing, with this modification it would take just 1 person and probably 5 minutes for each side. I think for many folks the advantages will be important--not just for trailering home, but also for fitting more aircraft in a hangar or to allow the aircraft to be kept in a standard 20' shipping container right on the airfield.

4) Aileron connection: The matched bellcranks of the Onex and the Thorp/Sunderland S-18 seem like a great way to accomplish this with minimal hassle. Any other ideas that I should consider?

5) Keep the proprietary spar caps? If they are to be cut anyway, and if an engineered solution for the wing fitting will have to be done/paid for, I wonder if it would be just as well to use a "standard" extrusion rather than custom CNC'ed $1000 spar caps sold by Sonex. Again, Sonex wants builders to use these spar caps, and I understand their reasons. But if we're already going off the reservation . . .

Precision-machined extruded Spar Caps.

(Above images from the Sonex web site: Sonex -- The Sport Aircraft Reality Check! )

Ideas/criticisms are solicited. Anybody know of someone who has done this already? I'm sure others have pondered this.

Last edited: