RCBinChicken

Active Member

- Joined

- May 19, 2019

- Messages

- 29

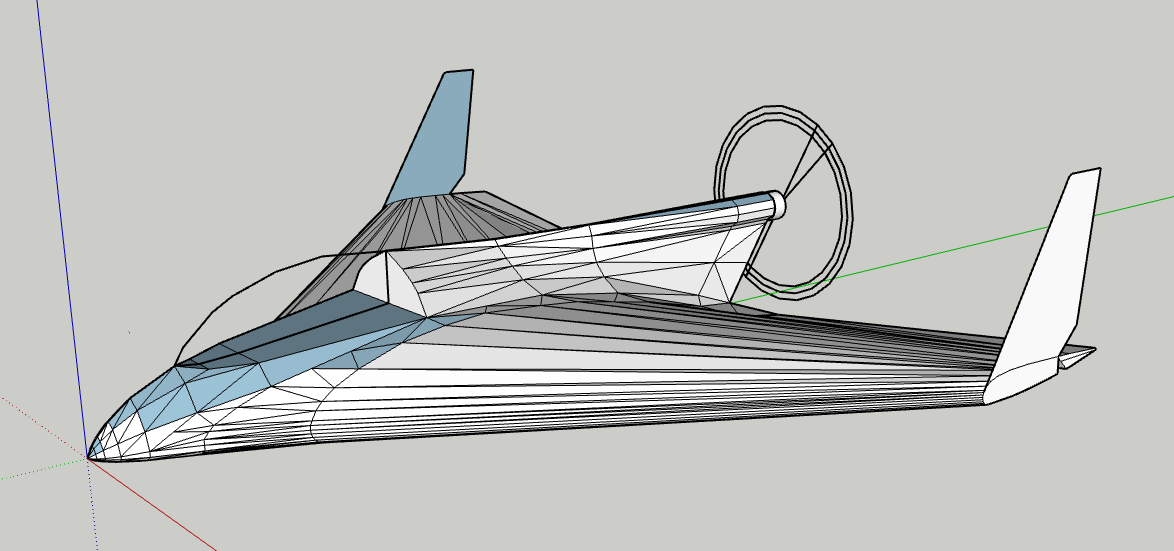

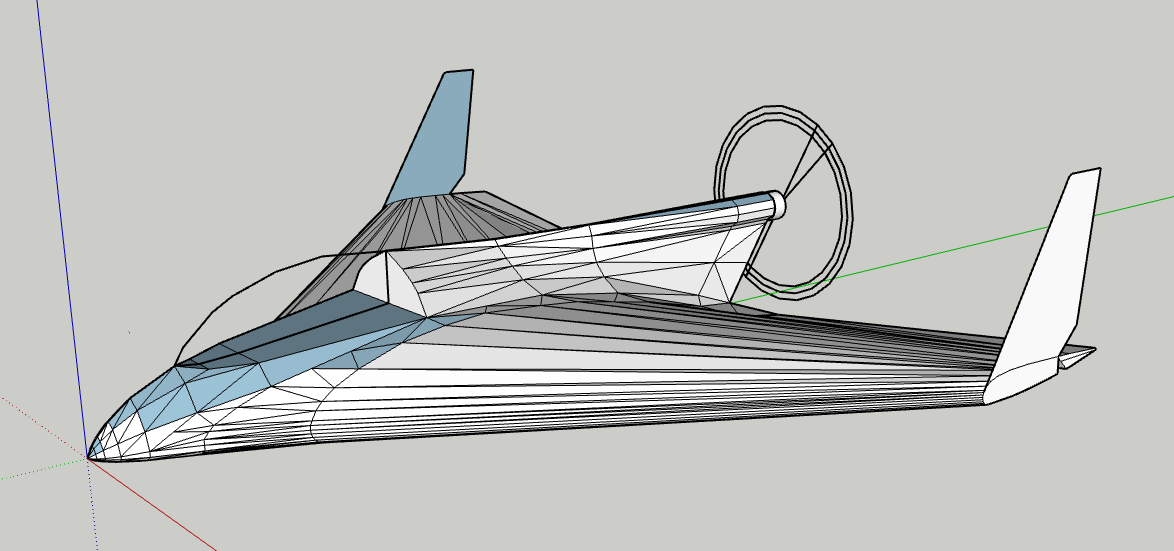

Hi all, after lots of lurking and reading threads pertaining to similar(ish) craft, I figured it was time to work up the nerve and show some of my designs, and find out exactly how bad they are.  This is a (scruffy) 3D model of my ideas so far, and in the time it took me to model it I've already thought of a lot of tweaks and things to fix... but at this stage, when I know that I know very little, better to get an iteration out and get to work on a Mk.II pronto than shoot for perfection.

This is a (scruffy) 3D model of my ideas so far, and in the time it took me to model it I've already thought of a lot of tweaks and things to fix... but at this stage, when I know that I know very little, better to get an iteration out and get to work on a Mk.II pronto than shoot for perfection.

Notes and/or sort-of-specs:

- Yes, I need to learn a real CAD package and stop using Sketchup. I'm hoping to pick up Fusion 360 over the next few weeks now polytechnic assignments have died down a little.

I'm hoping to pick up Fusion 360 over the next few weeks now polytechnic assignments have died down a little.

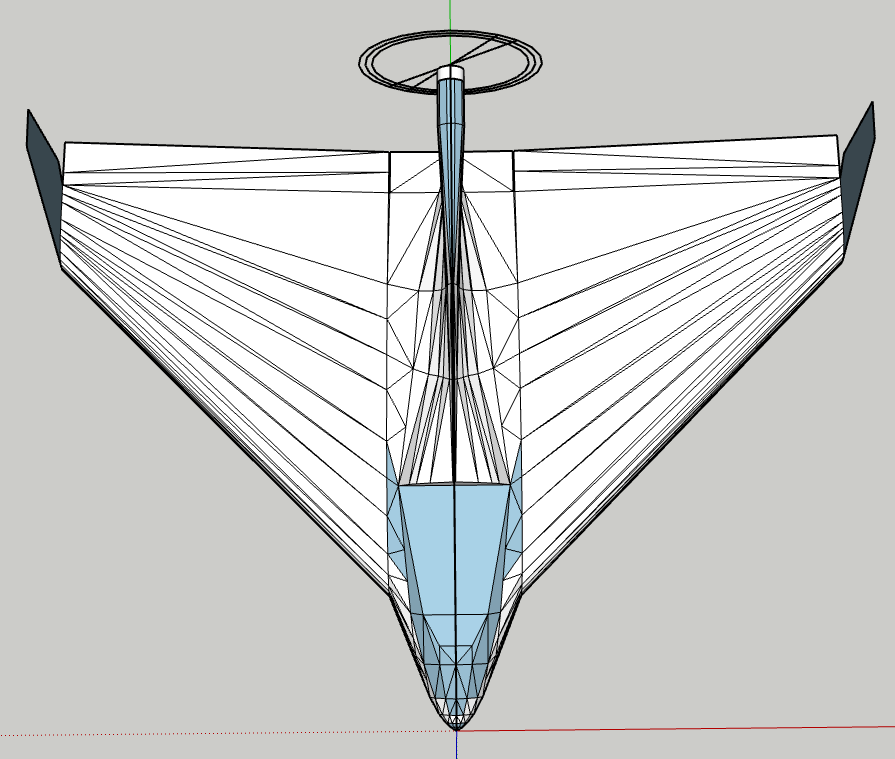

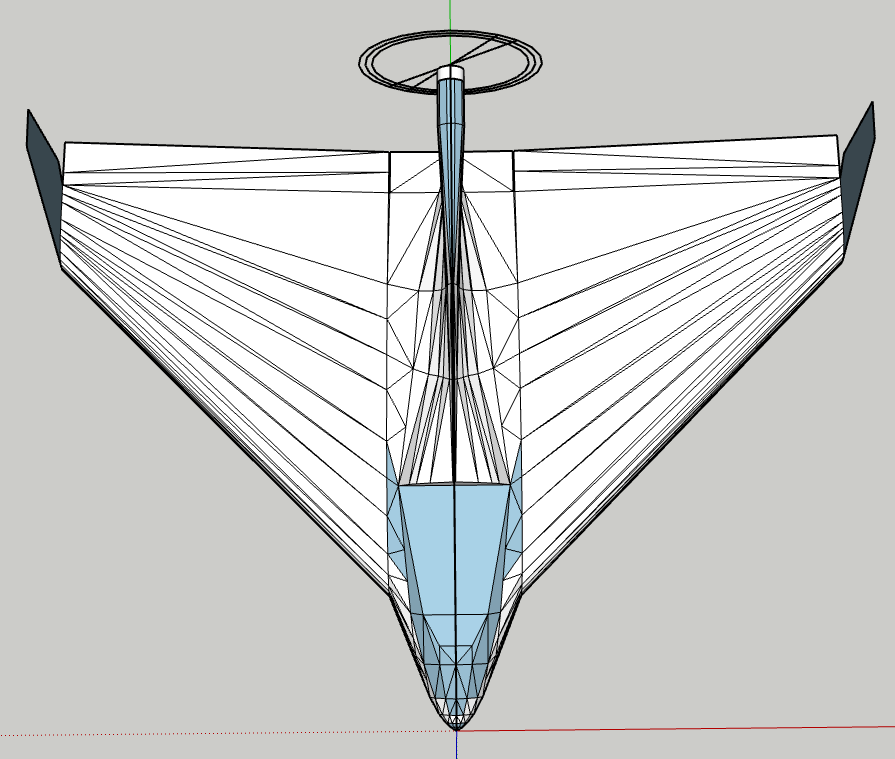

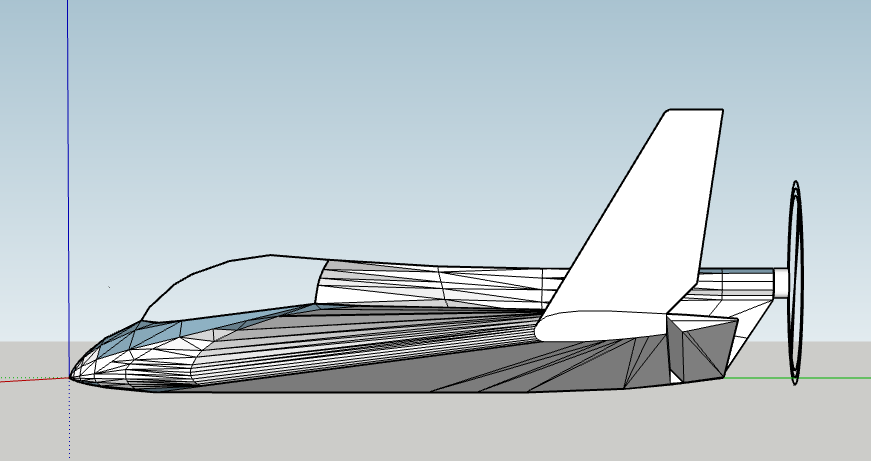

- This is intended to be a VERY light, slow flyer, a Wainfan Facetmobile/Rowe UFO wannabe specced down in both weight and power to occupy the wing-loading 'ecological niche' of the Sandlin Bloop. Wing area is 15m^2 (6m span, root chord 4-4.5m, tip chord 1m) which will give me just under 2lb/ft^2 wing loading, the figure Mike Sandlin quotes for the Bloop if I can keep empty weight around 70kg/154lb. (I weigh about the same.)

- Controls will be elevons and tip rudders, like the Facetmobile.

- Construction uncertain, as I have a lot to learn on the different methods and their merits, but likely fabric-covered, either wood or aluminium tubing for structure, foam under fabric for shaping.

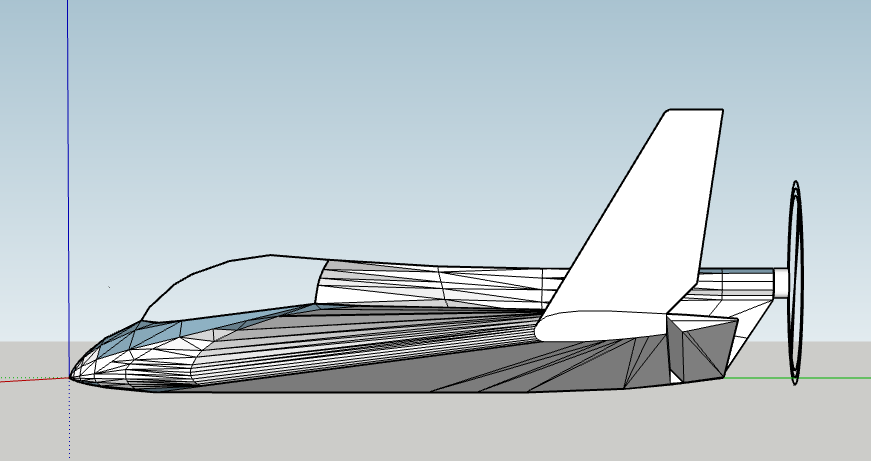

- The shaping will be simplified to facilitate construction - not quite to the Facetmobile's degree, but I know that all the compound curves I've put into the model here will make my life a misery in practice!

- Airfoil thickness, excluding the fuse bulge, is a roughly consistent 15% - though having read that the Facetmobile went right up to 18%, I might follow suit and go fully blended-wing-body on the next revision, to reduce parts count and wetted area a little more. The airfoils themselves are not something I know enough about to make a definite pick, but the root is going to be mostly flat-bottomed with a little reflex, thickest around 29-30% of chord, transitioning to a semi-symmetrical, more reflexed tip with a fair few degrees of washout.

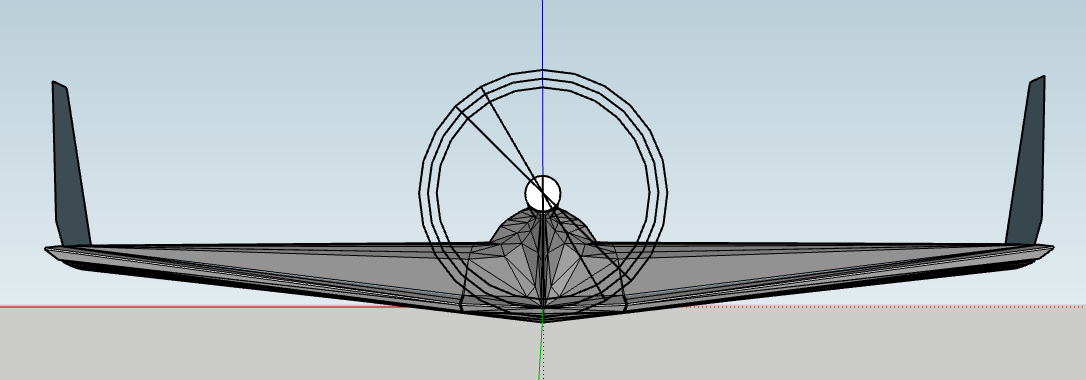

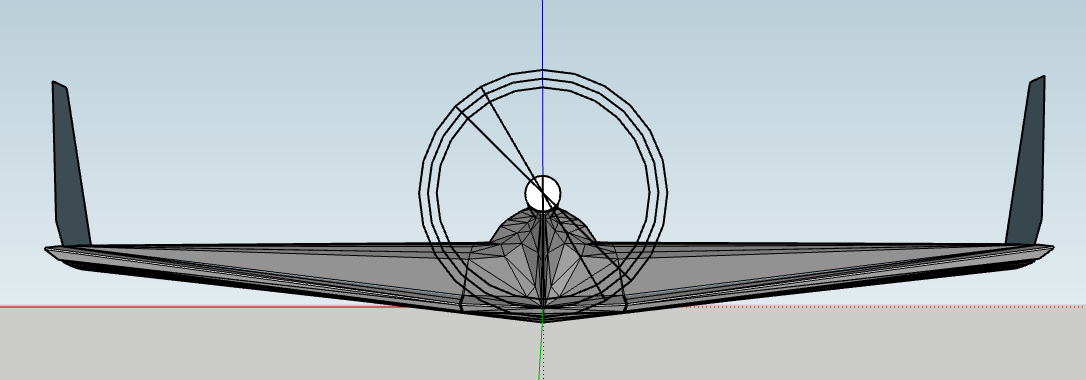

- Propulsion will be electric, a single brushless motor around the 20kW (25hp) mark, the same horsepower as the gas Moster 185 on the Bloop. Sandlin has estimated the Bloop cruises comfortably on a little under 11hp; I'm hoping my total drag will be non-trivially less than for a wire-braced biplane and thus for even lower cruise power requirements, but I'll err on the side of caution at this stage. Prop-diameter-wise, will be looking at 1.2-1.4m as that seems to be fairly tried-and-true for paramotor-class setups.

- I'm aware that within my intended weight target, on electric, flight time will be abysmal, and I'm happy to accept that; 20min or even a little less is fine by me. I'll gain a little fuel fraction benefit just on the weight of my powerplant; the beefier motor systems I've looked at, for motor and ESC etc., clock in at 6-7kg total compared to the Moster 185's 13kg, so that's a few minutes' extra LiPos I can cram in at least!

- Extremely rearward placement of the motor and prop is due to the aforementioned - the weight of the motor itself may be as little as 4kg, so its impact on CG placement will be negligible unless given a long moment arm, and I want the pilot pretty far forward for visibility at high AoA. Plus, a longer moment arm will enhance the stabilizing effect of a rear prop disc, so I may be able to cut down the wing-tip vert stabs a little and reduce their root bending loads.

- The aspect I'm questioning a little at present is the high thrust line. My initial justifications for it were that, in my experience with RC model aircraft, (1) it gets the prop disc up out of the pressure changes of the wing wake, considerably reducing noise and vibration loads on the prop blades, which are often cited as a primary disadvantage of pusher layouts, and (2) the only way I'll be able to manage a prop strike is if I land inverted. At RC scale, I've only found the downward pitching moment significant/problematic with far higher thrust lines than what I have here, but I'm aware that not everything translates perfectly from RC to full-scale... My optimistic assumption is that the wing dihedral should move the vertical CG and center of drag higher, and the far-rearward motor location means I'd hopefully only have to give a couple of degrees' down thrust to put the line through the CG again and neuter the pitching moment; but opinions most welcome.

At RC scale, I've only found the downward pitching moment significant/problematic with far higher thrust lines than what I have here, but I'm aware that not everything translates perfectly from RC to full-scale... My optimistic assumption is that the wing dihedral should move the vertical CG and center of drag higher, and the far-rearward motor location means I'd hopefully only have to give a couple of degrees' down thrust to put the line through the CG again and neuter the pitching moment; but opinions most welcome.

- That fin-like extrusion of the fuselage, with the motor at the end, does look like it needs to be a looooooooot thicker. That's a definite for the Mk.II.

- I have made no decisions regarding landing gear yet, as I'm too on-the-fence about the comparative pros and cons of every config I've seen so far.

Notes and/or sort-of-specs:

- Yes, I need to learn a real CAD package and stop using Sketchup.

- This is intended to be a VERY light, slow flyer, a Wainfan Facetmobile/Rowe UFO wannabe specced down in both weight and power to occupy the wing-loading 'ecological niche' of the Sandlin Bloop. Wing area is 15m^2 (6m span, root chord 4-4.5m, tip chord 1m) which will give me just under 2lb/ft^2 wing loading, the figure Mike Sandlin quotes for the Bloop if I can keep empty weight around 70kg/154lb. (I weigh about the same.)

- Controls will be elevons and tip rudders, like the Facetmobile.

- Construction uncertain, as I have a lot to learn on the different methods and their merits, but likely fabric-covered, either wood or aluminium tubing for structure, foam under fabric for shaping.

- The shaping will be simplified to facilitate construction - not quite to the Facetmobile's degree, but I know that all the compound curves I've put into the model here will make my life a misery in practice!

- Airfoil thickness, excluding the fuse bulge, is a roughly consistent 15% - though having read that the Facetmobile went right up to 18%, I might follow suit and go fully blended-wing-body on the next revision, to reduce parts count and wetted area a little more. The airfoils themselves are not something I know enough about to make a definite pick, but the root is going to be mostly flat-bottomed with a little reflex, thickest around 29-30% of chord, transitioning to a semi-symmetrical, more reflexed tip with a fair few degrees of washout.

- Propulsion will be electric, a single brushless motor around the 20kW (25hp) mark, the same horsepower as the gas Moster 185 on the Bloop. Sandlin has estimated the Bloop cruises comfortably on a little under 11hp; I'm hoping my total drag will be non-trivially less than for a wire-braced biplane and thus for even lower cruise power requirements, but I'll err on the side of caution at this stage. Prop-diameter-wise, will be looking at 1.2-1.4m as that seems to be fairly tried-and-true for paramotor-class setups.

- I'm aware that within my intended weight target, on electric, flight time will be abysmal, and I'm happy to accept that; 20min or even a little less is fine by me. I'll gain a little fuel fraction benefit just on the weight of my powerplant; the beefier motor systems I've looked at, for motor and ESC etc., clock in at 6-7kg total compared to the Moster 185's 13kg, so that's a few minutes' extra LiPos I can cram in at least!

- Extremely rearward placement of the motor and prop is due to the aforementioned - the weight of the motor itself may be as little as 4kg, so its impact on CG placement will be negligible unless given a long moment arm, and I want the pilot pretty far forward for visibility at high AoA. Plus, a longer moment arm will enhance the stabilizing effect of a rear prop disc, so I may be able to cut down the wing-tip vert stabs a little and reduce their root bending loads.

- The aspect I'm questioning a little at present is the high thrust line. My initial justifications for it were that, in my experience with RC model aircraft, (1) it gets the prop disc up out of the pressure changes of the wing wake, considerably reducing noise and vibration loads on the prop blades, which are often cited as a primary disadvantage of pusher layouts, and (2) the only way I'll be able to manage a prop strike is if I land inverted.

- That fin-like extrusion of the fuselage, with the motor at the end, does look like it needs to be a looooooooot thicker. That's a definite for the Mk.II.

- I have made no decisions regarding landing gear yet, as I'm too on-the-fence about the comparative pros and cons of every config I've seen so far.