stanislavz

Well-Known Member

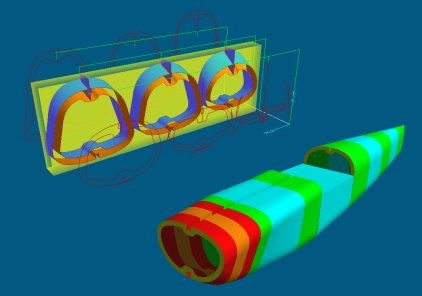

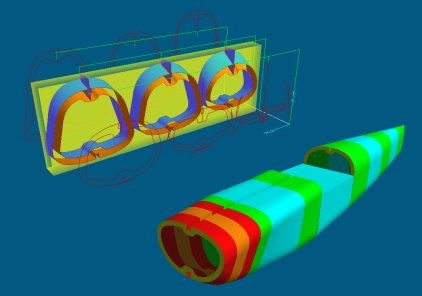

Wanted to post it into current cnc foam cutter thread, but I think, it is worth separate one. Making a fuse mold from foam slices.

Using this piece of software : http://www.devcad.com/eng/devfusfoam.asp

Tried with 10000 mm long fuselage, and 100 of slices - looks to be working slow, but ok. And you can make even thinner one slices, but cutting from same piece of foam, make sanding close to none,, and with foil on foam plug making - do it in really fast manner.

Using this piece of software : http://www.devcad.com/eng/devfusfoam.asp

Tried with 10000 mm long fuselage, and 100 of slices - looks to be working slow, but ok. And you can make even thinner one slices, but cutting from same piece of foam, make sanding close to none,, and with foil on foam plug making - do it in really fast manner.